1. Introduction

Tethered drone systems have gained increasing attention in various industries such as surveillance, telecommunications, and industrial inspections. Unlike traditional battery-powered drones, tethered drones receive continuous power from a ground station through a physical cable, enabling them to hover for extended periods without worrying about battery limitations.

However, designing a reliable tethered power system requires careful selection of the power supply and transmission cable. The wrong choice can lead to power losses, safety risks, and operational failures. This guide will walk you through the key considerations for selecting the right power supply and cable for your tethered drone application, helping you achieve efficient, safe, and long-lasting performance.

2. Understanding Power Requirements for Tethered Drones

The first step in designing a tethered drone power system is to understand the drone’s power consumption characteristics:

- Voltage and Current Needs: Most small to medium tethered drones operate at 12V to 48V DC, with current ranging from a few amps to over 20A depending on payload and motors.

- Power Consumption: Typical hover power might range from 100W to 500W or more.

- Onboard Battery vs. Tethered Power: While onboard batteries provide mobility, tethered power offers continuous supply, eliminating flight time constraints but introducing new design challenges.

Accurately estimating your drone’s power draw is crucial for selecting a power supply with adequate capacity and ensuring the cable can safely carry the required current.

3. Power Supply Selection

Selecting a power supply for a tethered drone system is not just about wattage and voltage—it is a system-level decision that directly affects cable selection, efficiency, weight, and safety.

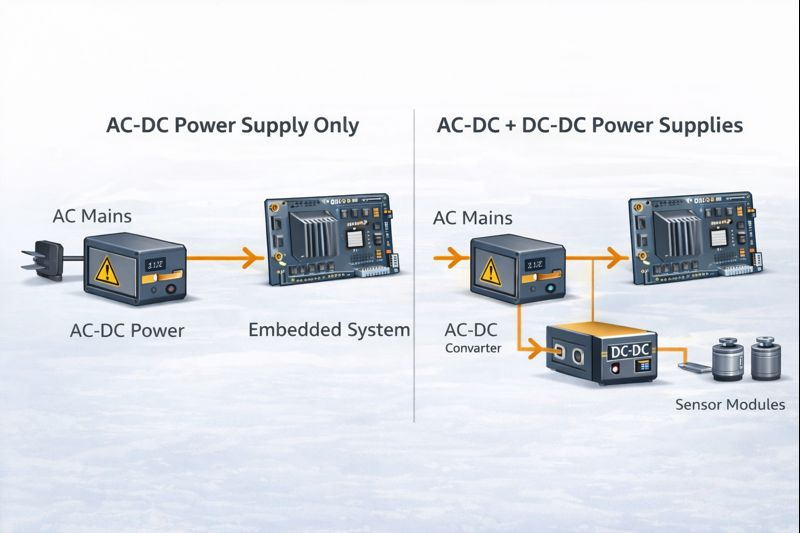

Before choosing a specific power supply model, it is important to determine where the AC-to-DC conversion will take place.

3.1 Power Transmission Architecture Overview

There are two primary power transmission architectures used in tethered drone systems:

- Ground Station AC-to-DC Conversion

- Onboard AC-to-DC Conversion (High-Voltage Transmission)

Each approach has distinct advantages and trade-offs, and the power supply selection must align with the chosen architecture.

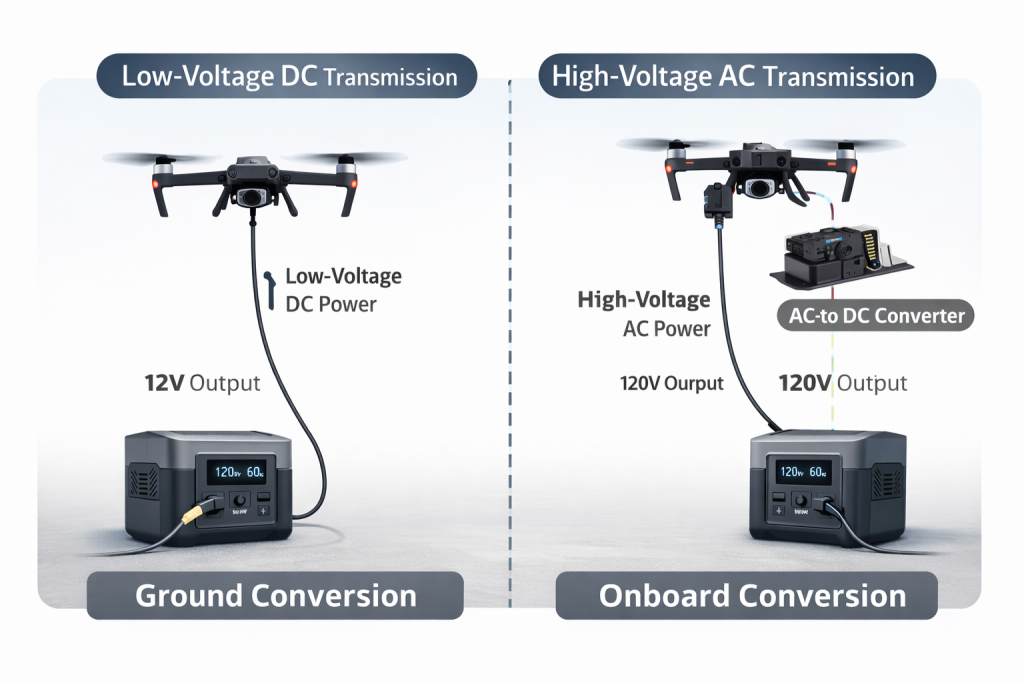

3.2 Option 1: Ground Station AC-to-DC Conversion

In this configuration, mains AC power (e.g., 120VAC) is converted to low-voltage DC—commonly 12V, 24V, or 48V—at the ground station. The DC power is then transmitted through the tether cable directly to the drone.

Key characteristics:

- Power supply is located entirely on the ground

- Drone electronics receive low-voltage DC directly

- Tether cable must carry higher current

Design considerations:

- The power supply must handle peak load currents with sufficient margin

- Cable gauge becomes critical due to higher current

- Voltage drop over cable length must be carefully calculated

This approach is well suited for short tether lengths, lower power systems, and designs that prioritize simplicity and onboard weight reduction.

3.3 Option 2: Onboard AC-to-DC Conversion (High-Voltage Transmission)

In this architecture, high-voltage AC (such as 120VAC or higher) is transmitted directly from the ground station to the drone. An onboard AC-to-DC converter then steps the voltage down to the required DC level.

Key characteristics:

- Lower current in the tether cable

- Thinner and lighter cables are possible

- AC-to-DC conversion occurs onboard the drone

Design considerations:

- The onboard power supply must be compact, lightweight, and efficient

- Thermal management on the drone becomes critical

- Higher voltage requires stricter insulation and safety measures

This method is commonly used in commercial and long-tether applications, where cable weight and aerodynamic drag must be minimized.

3.4 Power Supply Rating and Performance Criteria

Regardless of the chosen architecture, the following factors should guide power supply selection:

- Rated Output Power

Select a power supply with at least 20–30% headroom above the maximum expected load to ensure stable operation and long-term reliability.

For example, a drone drawing 12A at 12V (144W) should use a power supply rated at 180W–200W or higher. - Voltage Output and Current Capacity

Output voltage must match system requirements, and current capability must support peak loads without derating. - Efficiency and Thermal Management

Higher efficiency reduces heat generation and improves overall system reliability. Adequate cooling or heat sinking is essential, especially for onboard converters. - Power Supply Form Factor and Weight

Compact, lightweight designs are critical for onboard applications, while ground-based systems can tolerate larger enclosures.

3.5 Common Power Supply Options

Industrial AC-to-DC power supplies from reputable manufacturers are often used in tethered drone systems. Brands such as Mean Well offer compact and efficient solutions suitable for both ground station and onboard use.

For example, models like the RPS-300-12 provide 12V output with sufficient current capacity and are commonly evaluated for tethered drone power applications, depending on system architecture and weight constraints.

3.6 AC vs. DC Transmission Summary

- Low-voltage DC transmission simplifies drone electronics but increases cable current and weight.

- High-voltage AC transmission reduces cable losses and weight but adds onboard complexity and safety requirements.

The optimal choice depends on tether length, power level, drone payload capacity, and operational environment.

4. Cable Selection for Tethered Power Transmission

Cable selection is one of the most critical design challenges in tethered drone systems. The cable not only transmits electrical power but also directly impacts flight stability, maximum altitude, efficiency, and overall system safety.

The optimal cable specification depends heavily on the chosen power transmission architecture discussed in Section 3.

4.1 Key Cable Selection Parameters

Regardless of system architecture, the following parameters must always be evaluated:

- Current carrying capacity

- Voltage rating and insulation level

- Cable length and resulting voltage drop

- Weight, flexibility, and mechanical strength

- Environmental resistance (temperature, abrasion, UV)

Ignoring any of these factors can result in excessive losses, overheating, or unsafe operation.

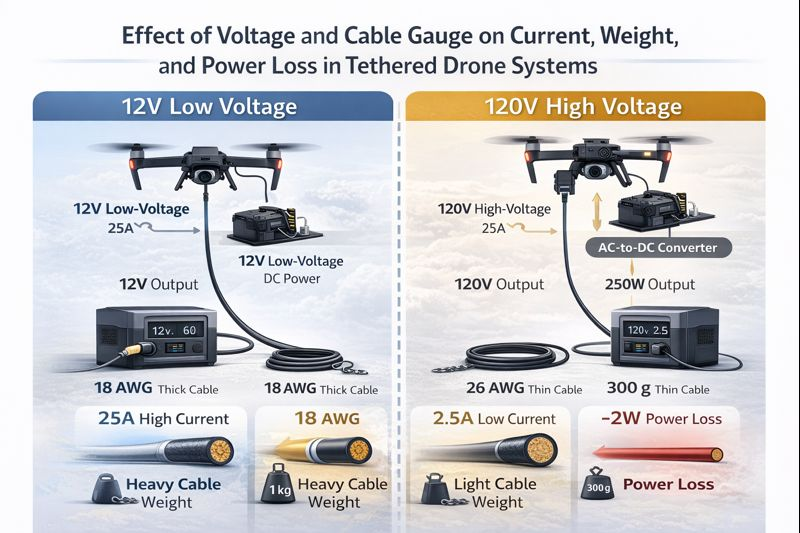

4.2 Cable Requirements for Low-Voltage DC Transmission

When DC power (e.g., 12V–48V) is transmitted from the ground station to the drone, the tether cable must carry relatively high current.

Design implications:

- Higher current requires thicker conductors (lower AWG number)

- Cable weight increases rapidly with current rating

- Voltage drop becomes a dominant design constraint

Example:

A drone drawing 12A at 12V over a long tether length will experience significant voltage drop if thin cables such as 20 AWG are used. In many cases, 18 AWG or thicker conductors are required to maintain stable voltage at the drone.

This approach is typically suitable for:

- Short tether lengths

- Lower power systems

- Applications prioritizing electrical simplicity

4.3 Cable Requirements for High-Voltage Transmission

When high-voltage AC or DC power is transmitted to the drone, the required current is significantly reduced for the same power level.

Design implications:

- Thinner conductors can be used while maintaining safety margins

- Cable weight and aerodynamic drag are reduced

- Longer tether lengths become feasible

Example:

Transmitting 300W at 120VAC requires only 2.5A, compared to 25A at 12V DC. This reduction allows the use of much lighter cables without excessive losses.

However, higher transmission voltage introduces:

- Stricter insulation and creepage requirements

- Increased safety considerations during handling and operation

This approach is commonly used in commercial tethered drone systems and long-duration hover applications.

4.4 Understanding Wire Gauge (AWG) and Current Limits

American Wire Gauge (AWG) defines conductor size and current capacity:

- Higher AWG number → thinner wire → lower current capacity

- Lower AWG number → thicker wire → higher current capacity

While tables provide general current ratings, real-world conditions such as cable bundling, ambient temperature, and airflow must also be considered.

For tethered drones, conservative derating is recommended to avoid overheating in airborne cables.

4.5 Voltage Drop and Power Loss Considerations

Voltage drop increases with:

- Cable length

- Current

- Conductor resistance

Excessive voltage drop can cause:

- Reduced motor performance

- Instability during hover

- Increased thermal stress on electronics

As a rule of thumb:

- Keep voltage drop below 5% for stable drone operation

- Increase conductor size or transmission voltage if limits are exceeded

4.6 Mechanical and Aerodynamic Considerations

Unlike stationary systems, tethered drone cables must also meet mechanical requirements:

- Low weight to minimize lift loss

- High flexibility to reduce drag-induced oscillations

- Adequate tensile strength to support vertical deployment

- Abrasion resistance for repeated use

Specialized tether cables are often used, combining lightweight insulation with reinforced strength members.

4.7 Practical Cable Selection Recommendations

- Use low-voltage DC transmission only for short distances and modest power levels

- Consider high-voltage transmission when cable weight or tether length becomes critical

- Always verify cable voltage rating exceeds system voltage with sufficient margin

- Test cable temperature rise under continuous load before flight

- Inspect cables regularly for wear, insulation damage, or conductor fatigue

4.8 Cable Selection Summary

Cable selection should never be treated as an afterthought in tethered drone design. It must be evaluated together with power supply architecture, safety protection, and mechanical constraints.

A well-chosen cable improves efficiency, stability, and safety—while a poor choice can limit performance or create serious hazards.

5. Safety and Protection Measures for Tethered Drone Power Systems

Safety is a critical design requirement in tethered drone systems. Unlike battery-powered drones, tethered systems involve continuous electrical connection between the ground station and the airborne platform, introducing additional electrical and mechanical risks.

A robust protection strategy must address electrical faults, mechanical failures, and human safety.

5.1 Overcurrent Protection at the Ground Station

Overcurrent protection is essential to prevent damage caused by short circuits, overloads, or cable failures.

Recommended practices:

- Install fast-acting fuses or miniature circuit breakers (MCBs) at the ground station

- Select trip ratings slightly above normal operating current to avoid nuisance trips

- Ensure devices are rated for the system voltage (AC or DC as applicable)

Ground-side protection ensures faults are isolated quickly without adding weight or complexity to the drone.

5.2 Cable Fault and Break Detection

A tether cable is subject to mechanical stress, vibration, and environmental exposure. Cable failure can result in short circuits, arcing, or uncontrolled power delivery.

Mitigation strategies include:

- Immediate power shutdown upon overcurrent detection

- Mechanical strain relief at both cable ends

- Use of connectors designed to fail safely under excessive tension

Advanced systems may implement active monitoring to detect abnormal current or voltage behavior indicative of cable damage.

5.3 High-Voltage Safety Considerations

When using high-voltage AC or DC transmission, additional precautions are required:

- Use cables with voltage ratings exceeding system voltage with adequate margin

- Ensure proper insulation, creepage, and clearance distances

- Prevent exposed conductors or connectors during operation

Clear labeling and controlled access around the ground station are strongly recommended to reduce risk to operators and bystanders.

5.4 Thermal Protection and Power Supply Safeguards

Both ground-based and onboard power supplies generate heat during continuous operation.

Best practices include:

- Selecting power supplies with built-in over-temperature protection

- Ensuring adequate airflow or heat sinking

- Avoiding operation near maximum rated limits for extended periods

Thermal stress is a common cause of long-term reliability issues if not properly managed.

5.5 Ground Fault and Leakage Protection

In systems powered from mains electricity, ground fault protection adds an important safety layer.

- Ground fault circuit interrupters (GFCIs) can disconnect power in case of leakage

- Proper grounding of the ground station enclosure reduces shock risk

- Leakage current limits should comply with applicable safety standards

This is particularly important for outdoor or public-area deployments.

5.6 Emergency Power Shutdown and Operational Safety

An emergency shutdown mechanism allows operators to quickly disconnect power in unexpected situations.

Recommended features:

- Manual emergency stop switch at the ground station

- Clear visibility and accessibility of disconnect controls

- Defined emergency procedures for operators

Operational safety procedures are as important as hardware protection.

5.7 Safety System Design Summary

A well-designed tethered drone safety system should:

- Isolate electrical faults rapidly

- Minimize risk during cable damage or disconnection

- Protect operators, bystanders, and equipment

- Match protection strategies to the chosen power transmission architecture

Safety should be considered from the earliest design stage and validated through testing under realistic operating conditions.

6. Practical Tips and Recommendations

- Balance Cable Weight and Power Capacity: Optimize cable thickness to safely carry current while minimizing weight to reduce drag.

- Consider Environment: Account for temperature, humidity, and mechanical wear in cable and component selection.

- Test Thoroughly: Before flight, perform electrical tests to confirm voltage levels, temperature rise, and safety system function.

- Regular Maintenance: Inspect cables and connectors regularly for wear, corrosion, or damage to ensure ongoing safety.

7. Conclusion

Selecting the right power supply and cable is foundational to building a reliable tethered drone system. Properly sizing your power components ensures efficient operation, reduces risk, and extends equipment life.

If you’re working on a tethered drone project and want more detailed recommendations or product suggestions, feel free to reach out. Designing safe and efficient tethered power solutions is our specialty!