Energy efficiency standards have become a critical consideration for power supply manufacturers and OEM clients alike. In particular, DOE Level VI in the United States and EU CoC Tier 2 in Europe set stringent requirements for external power supplies, compelling manufacturers to optimize their products for reduced energy consumption. Compliance is not only a regulatory necessity but also a reflection of technical expertise and reliability. This article explores the logic behind these standards and why manufacturers must align their products accordingly.

1. Overview of DOE Level VI Standard

The Department of Energy (DOE) Level VI standard, implemented in 2016, defines minimum efficiency and maximum no-load power requirements for external power supplies. Key points include:

- Efficiency requirements: Specifies minimum energy conversion efficiency at various load levels.

- No-load power limits: Reduces energy waste when the adapter is plugged in but not powering a device.

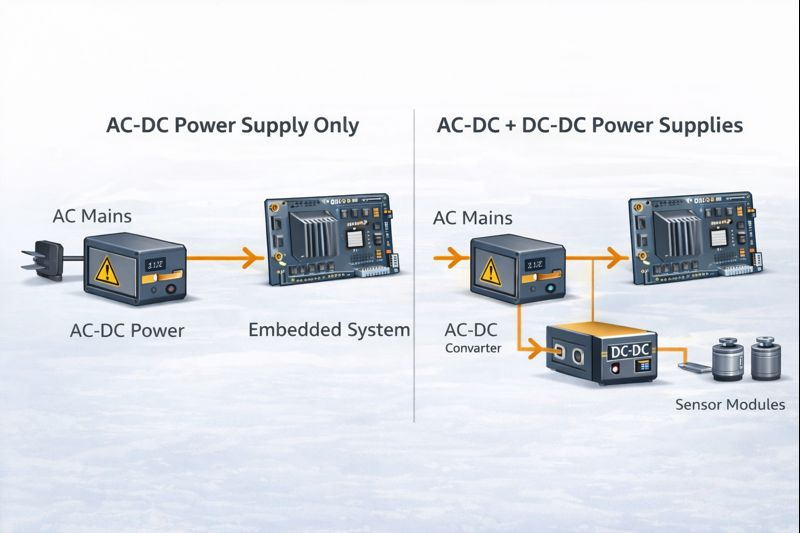

- Product coverage: Applies to a wide range of AC-DC external power supplies commonly used in consumer electronics and industrial equipment.

For OEM clients, selecting a manufacturer capable of producing DOE Level VI compliant adapters ensures products meet regulatory requirements while minimizing energy consumption and operating costs.

2. Overview of EU CoC Tier 2 Standard

The EU Code of Conduct (CoC) Tier 2 standard represents Europe’s push toward sustainable electronics. Its main objectives include improving power supply efficiency, reducing energy losses, and promoting environmentally friendly manufacturing. Key aspects:

- Efficiency metrics: Defines minimum conversion efficiency under different load conditions.

- No-load loss and thermal performance: Sets strict limits to minimize idle energy loss and prevent overheating.

- Certification and verification: Requires testing by accredited labs to validate compliance.

Manufacturers face technical challenges in meeting these standards, including advanced circuit design, component selection, and rigorous testing.

3. Compliance Logic for Manufacturers

Why must manufacturers comply? The logic is multi-faceted:

- Legal and Market Access: Non-compliance can prevent entry into major markets like the U.S. and EU.

- Technical Advancement: Meeting these standards drives product innovation, optimized efficiency, and reduced energy loss.

- Brand Trust and Reliability: Compliance signals product safety and quality to OEM clients, minimizing potential recalls or warranty issues.

- Cost Efficiency and Competitiveness: Early adoption reduces retrofitting costs and positions manufacturers competitively in energy-conscious markets.

4. How Manufacturers Achieve Compliance

Manufacturers implement a combination of design, testing, and production strategies to meet DOE Level VI and EU CoC Tier 2 requirements:

- R&D Design Optimization: Enhancing circuitry for better conversion efficiency and lower standby power consumption.

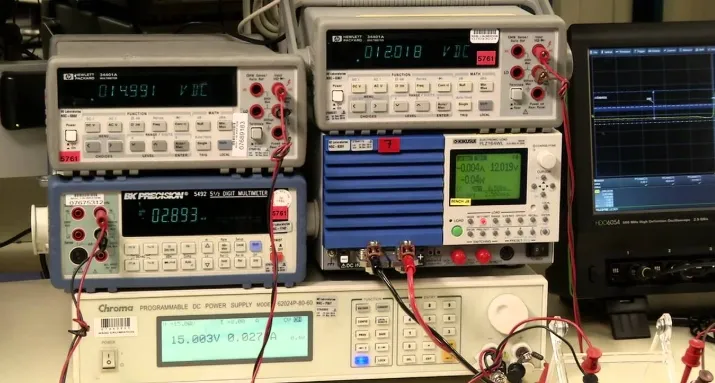

- Testing and Verification: Performing no-load and full-load efficiency tests, often with third-party certification.

- Material and Process Improvements: Using high-quality components, thermal management techniques, and low-loss transformers.

- Continuous Monitoring: Updating designs and manufacturing processes to keep up with evolving regulations.

Shenzhen Xinjukang Technology (XJK Power) Co., LTD applies these strategies across its product line, including high-wattage and medical power adapters, ensuring both compliance and performance excellence.

5. Implications for OEM Clients

OEM clients should prioritize suppliers with demonstrated compliance capabilities:

- Reduced Regulatory Risk: Products meet legal requirements in target markets.

- Enhanced Product Reliability: High-efficiency, tested power supplies reduce failure rates and energy costs.

- Partnering with Experts: Choosing a manufacturer like XJK Power ensures access to technical expertise, compliant designs, and long-term support.

Conclusion & Call to Action

DOE Level VI and EU CoC Tier 2 standards are more than regulatory obligations—they reflect a manufacturer’s technical competence and commitment to energy efficiency. For OEM clients, working with compliant suppliers mitigates risk, ensures reliability, and aligns with sustainable practices.

Shenzhen Xinjukang Technology (XJK Power) Co., LTD combines advanced R&D, stringent testing, and process optimization to deliver power supplies that meet or exceed global efficiency standards. OEM clients seeking reliable, high-performance, and compliant solutions are encouraged to contact XJK Power today to discuss project requirements.