For OEM clients, choosing the right power supply manufacturer is not just about price and delivery—it is about ensuring the long-term stability, safety, and compliance of their products. A power supply is the heartbeat of any electronic device, and if the manufacturer lacks strong technical capabilities, it can lead to costly delays, quality issues, or even regulatory failures.

This article outlines five essential factors OEM customers should assess when evaluating a power supply partner’s technical strength, helping you minimize risk and select a supplier capable of supporting complex, large-scale, or specialized projects.

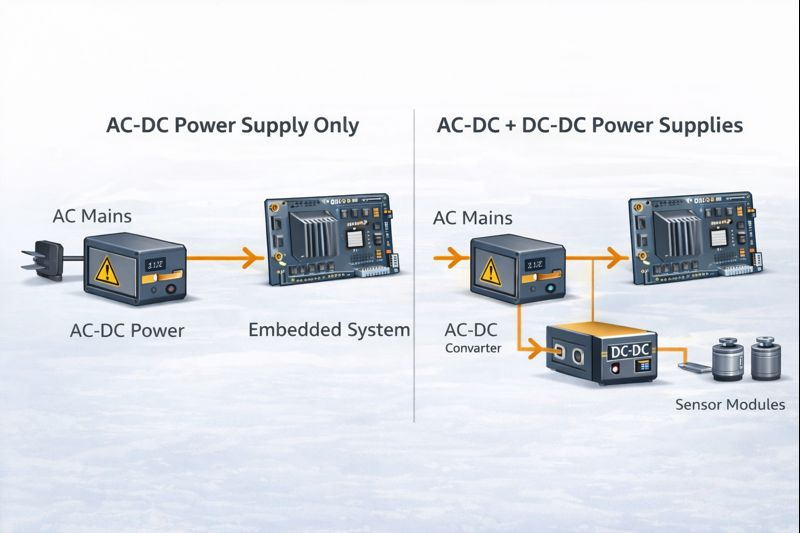

1. Research and Development (R&D) Capabilities

A manufacturer’s R&D capabilities directly influence its ability to deliver innovative and reliable solutions. Look for:

- Dedicated engineering teams specializing in your industry segment (e.g., medical, industrial, or high-power applications).

- Custom design capabilities that go beyond standard catalog products.

- Rapid prototyping and response to technical challenges during development.

For example, Shenzhen Xinjukang Technology (XJK Power) Co., LTD maintains a highly skilled R&D team that focuses on high-wattage adapters (up to 120W), medical-grade power supplies, and PoE solutions. This allows OEM clients to receive tailored designs with faster turnaround times.

2. Certifications and Compliance

Regulatory compliance is non-negotiable, especially in sectors like healthcare, industrial automation, and telecommunications. Key certifications to look for include:

- Safety standards: UL, CE, FCC, CB, IEC60601 (for medical)

- Environmental compliance: RoHS, REACH

- Quality management systems: ISO 9001, ISO 13485 (for medical devices)

A technically strong supplier will not only hold these certifications but will also integrate compliance into its design and production process. XJK Power’s medical power supplies, for instance, comply with IEC60601-1 standards, ensuring safety for critical medical devices.

3. Manufacturing Process and Equipment

Technical strength is also reflected in the production environment. Evaluate:

- Advanced manufacturing equipment, including automated SMT lines and precision assembly stations.

- Strict production controls, such as component traceability and controlled environments for sensitive products.

- Capacity for large-scale production without sacrificing quality consistency.

XJK Power operates modern manufacturing facilities equipped with automated lines and aging test chambers to guarantee performance consistency, even for large OEM orders.

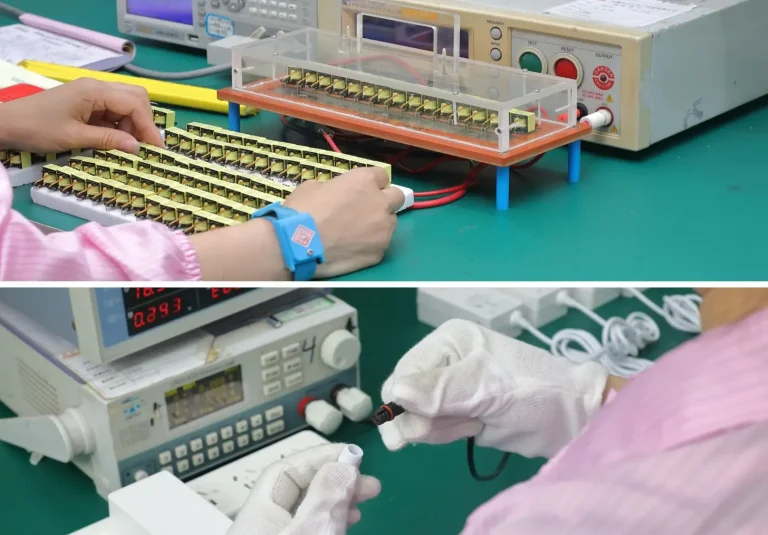

4. Quality Control and Testing

Consistent quality is the result of rigorous testing and systematic control. When assessing a supplier, ask about:

- Incoming quality control (IQC) and in-process inspections (IPQC).

- Final quality control (FQC) and outgoing quality control (OQC) procedures.

- Reliability tests, such as high/low temperature, surge, and EMC testing.

At XJK Power, every adapter undergoes comprehensive testing, including 100% burn-in and high-voltage testing, to ensure safety and long-term performance.

5. After-Sales Support and Technical Service

A power supply’s life cycle does not end after shipment. A capable supplier should offer:

- Technical troubleshooting and on-site support for OEM partners.

- Engineering collaboration for product upgrades or regulatory changes.

- Long-term availability and spare parts planning to ensure supply continuity.

XJK Power provides dedicated technical support teams to assist OEM clients throughout the product life cycle, from initial integration to after-sales service.

Conclusion & Call to Action

Evaluating a power supply manufacturer’s technical strength is critical for OEM success. By focusing on R&D, compliance, manufacturing, quality control, and after-sales service, you can mitigate risks and establish a reliable supply chain.

As a trusted partner in high-wattage, medical, and custom power solutions, Shenzhen Xinjukang Technology (XJK Power) Co., LTD combines advanced engineering with stringent quality standards to help OEM clients achieve their goals efficiently and safely.

Looking for a technically capable power supply partner? Contact XJK Power([email protected]) today to discuss your project requirements and explore customized solutions tailored to your industry needs.