In lithium battery–powered equipment, charging behavior is defined not by the external power source, but by the electrical expectations of the internal battery management system (BMS). Misunderstanding this point often leads to incorrect power selection, reduced efficiency, or long-term reliability issues.

This article explains—strictly from an electrical and system-design perspective—why a regulated DC power adapter or DC-DC converter is required, and why alternatives such as transformers or solar charge controllers are often misapplied.

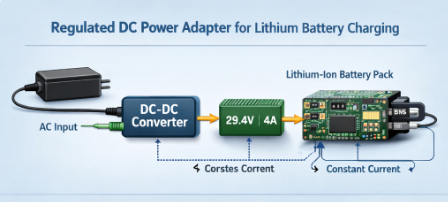

1. The Role of the Original AC Power Adapter

An original AC power adapter supplied by an equipment manufacturer is not a generic accessory. Electrically, it serves a precise function:

- Converts AC mains to regulated DC

- Provides a fixed output voltage

- Limits output current within a defined range

- Matches the charging profile expected by the internal BMS

For example, a typical specification such as:

- Output Voltage: 29.4 V DC

- Output Current: 4.0 A

- Maximum Power: ~120 W

Strongly indicates a 7-series (7S) lithium battery architecture, where 29.4 V represents the full-charge voltage (7 × 4.2 V).

From a system perspective, the AC adapter is already a DC power supply reference.

Any replacement solution must replicate this electrical behavior.

2. Why This Is Not a Transformer Selection Problem

In battery-powered systems, both the energy source and the load operate on direct current (DC).

- Transformers function only with alternating current (AC)

- They provide no voltage regulation in DC systems

- They cannot enforce charging voltage limits required by lithium batteries

Therefore, replacing an AC adapter in a battery-driven environment is not a transformer problem, but a DC voltage regulation problem.

3. Misuse of Solar Charge Controllers in Battery-to-Battery Systems

Solar charge controllers are often introduced as an intermediary because they can regulate voltage and support lithium batteries. However, they are optimized for a fundamentally different input source.

From an engineering standpoint:

- Solar controllers assume variable, current-limited sources

- Battery inputs are low-impedance, high-current sources

- Control algorithms are mismatched for battery-to-battery operation

As a result:

- Conversion stages are redundant

- System efficiency is reduced

- Thermal and long-term reliability margins are compromised

In non-solar applications, a solar controller does not add functional value.

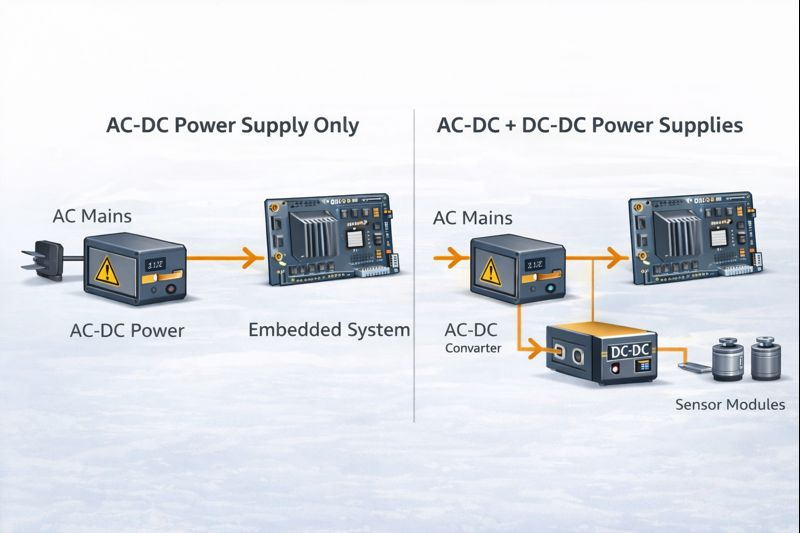

4. Correct Engineering Approach: Regulated DC-DC Power Conversion

When a higher-voltage lithium battery pack is used as the input source, the correct solution is a regulated DC-DC buck power adapter.

From a design standpoint, this solution:

- Enforces the exact output voltage required by the BMS

- Limits current within safe operating boundaries

- Maintains predictable thermal behavior

- Simplifies system architecture

Typical Electrical Requirements

- Input Voltage Range: 30–60 V DC

- Output Voltage: Fixed, regulated (e.g. 29.4 V DC)

- Output Current: ≥ rated charging current

- Power Rating: ≥ 20–30% above nominal load

- Protections: Over-voltage, over-current, short-circuit, over-temperature

This configuration directly mirrors the electrical role of the original AC adapter.

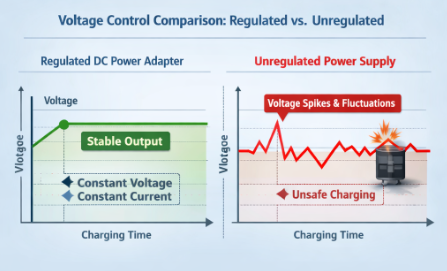

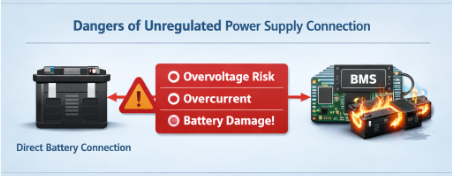

5. Risk Considerations in Improper Power Selection

From a reliability and safety perspective, the following practices introduce significant risk:

- Directly connecting raw battery voltage to the load

- Using unregulated or poorly regulated converters

- Operating power modules at their maximum rated output continuously

- Ignoring environmental derating (temperature, enclosure, airflow)

Lithium battery systems tolerate very little deviation from their expected charging voltage.

6. Engineering Conclusion

In lithium battery charging systems, the charging interface is defined by voltage regulation, not by the energy source type.

Replacing proprietary chargers or intermediate controllers requires:

- Understanding the original adapter’s electrical role

- Replicating its regulated DC behavior

- Selecting power modules with sufficient protection and derating margins

A properly selected DC power adapter or DC-DC converter provides the most reliable, efficient, and scalable solution for battery-driven applications across industrial, mobility, and portable power systems.

More tips about how to choose a dc power adapter please refer: https://xjkadapter.com/how-to-choose-a-dc-power-adapter-for-lithium-battery-chargers/.