1. Introduction

Power supplies are the backbone of virtually every electronic device, ensuring stable voltage, safety, and efficiency. For OEM clients, selecting the right power supply is critical—not only to meet performance requirements but also to comply with international energy standards and certifications. With a wide variety of power supply types available, understanding the technical differences and application scenarios is essential. This article provides a comprehensive guide to help OEM clients make informed decisions and highlights how Shenzhen Xinjukang Technology (XJK Power) delivers reliable, high-performance solutions.

2. Overview of Power Supply Types

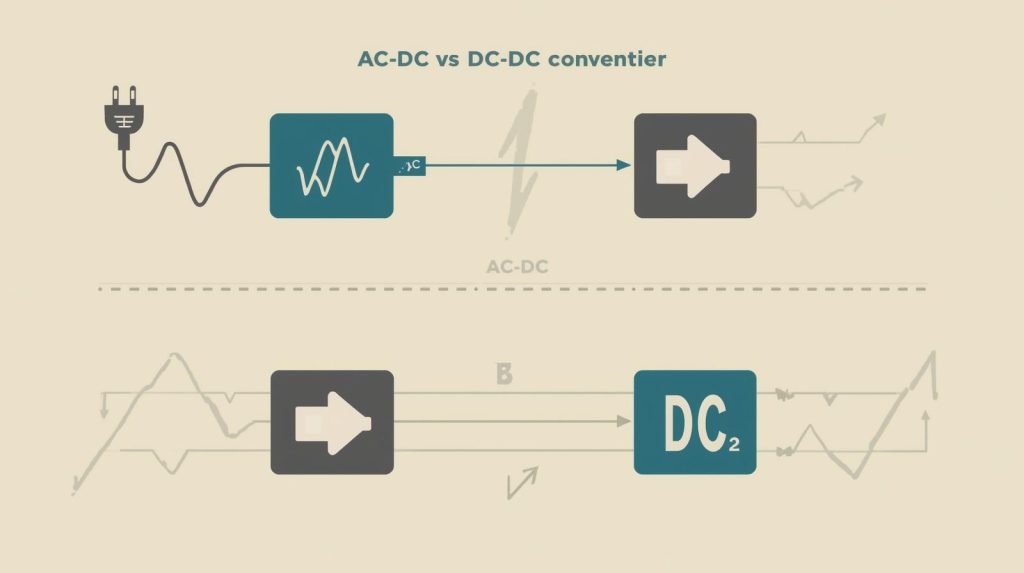

Power supplies can be categorized based on design principles, output type, and application requirements. The main types commonly used in OEM applications include:

- AC-DC and DC-DC power supplies

- Linear and Switching power supplies

- High-wattage power supplies

- Medical power supplies

- POE (Power over Ethernet) solutions

- Custom or bare board solutions

Each type has unique characteristics, advantages, and limitations. Understanding these distinctions is key for OEM clients seeking optimal performance and compliance. More details, please refer to our link.

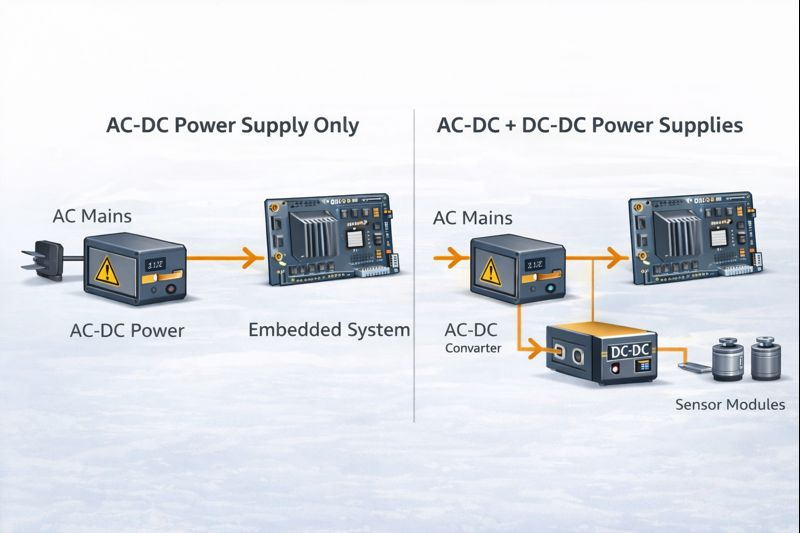

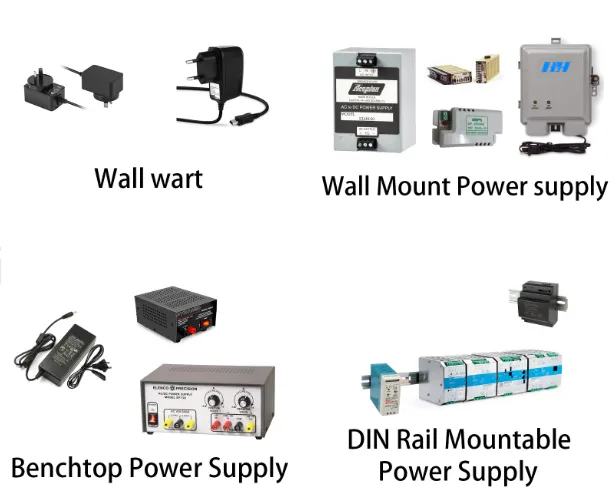

3. AC-DC vs DC-DC Power Supplies

AC-DC Power Supplies

AC-DC converters transform alternating current (AC) into direct current (DC). These supplies are widely used in consumer electronics, industrial equipment, and office devices. Their main advantages include stable output and broad applicability. However, they tend to be larger in size and may have lower efficiency compared to DC-DC solutions.

DC-DC Power Supplies

DC-DC converters convert one DC voltage level to another. They are often employed in embedded systems, communication devices, and industrial controls. DC-DC supplies are compact, highly efficient, and offer flexible output options. The primary considerations include thermal management and electromagnetic interference (EMI).

4. Linear vs Switching Power Supplies

Linear Power Supplies

Linear power supplies regulate voltage using a linear control mechanism. They offer low output noise and excellent stability, making them suitable for laboratory instruments and audio equipment. The drawbacks are lower efficiency and larger size.

Switching Power Supplies

Switching power supplies regulate output voltage through high-speed switching techniques. They are more efficient, compact, and lightweight than linear supplies. However, switching designs produce higher output noise and typically require additional filtering. These supplies are ideal for industrial, medical, and high-power applications.

5. Specialized Power Supply Types

High-Wattage Power Supplies

High-wattage solutions, such as 120W or 240W adapters, are designed for demanding industrial or server applications. Key design considerations include heat dissipation, long-term reliability, and stable output under heavy loads.

Medical Power Supplies

Medical-grade power supplies must meet strict certifications such as UL60601 or EN60601. They prioritize patient safety with low leakage current, stable output, and high reliability, and are commonly used in diagnostic equipment and clinical devices.

POE (Power over Ethernet) Power Supplies

POE supplies deliver power through standard Ethernet cables, reducing cabling requirements for network devices. Key considerations include maximum load limits and overall energy efficiency.

Custom / Bare Board Solutions

OEM clients often require custom power solutions tailored to specific dimensions, outputs, interfaces, and power ratings. Design priorities include thermal management, efficiency, EMC compliance, and long-term operational stability. Shenzhen Xinjukang Technology (XJK Power) offers extensive experience in delivering customized power solutions to meet these requirements.

6. How to Choose the Right Power Supply for OEM Applications

When selecting a power supply, OEM clients should consider:

- Power Requirements: Total wattage, voltage, and current specifications.

- Efficiency and Compliance: Conformance with DOE Level VI, EU CoC Tier 2, and other relevant standards.

- Safety and Reliability: Protection against short circuits, overload, and overheating.

- Cost vs Performance: Balancing upfront costs with efficiency and long-term operational benefits.

- Supplier Expertise: Partnering with manufacturers that have proven R&D, testing, and OEM customization capabilities.

Shenzhen Xinjukang Technology (XJK Power) combines advanced R&D, rigorous testing, and process optimization to provide high-performance, compliant power solutions tailored for OEM applications.

7. Case Study / Example

For example, XJK Power offers:

- 120W high-wattage adapters for industrial and communication equipment

- Medical power supplies meeting UL60601 and EN60601 standards

- POE power solutions for networking applications

- Custom power solutions tailored to OEM specifications

These products undergo extensive testing for efficiency, stability, and compliance, ensuring reliability for demanding OEM projects.

8. Conclusion

Understanding the different types of power supplies is crucial for OEM clients aiming to select the right solution for their applications. Factors such as efficiency, safety, compliance, and supplier capability should guide the decision-making process. Shenzhen Xinjukang Technology (XJK Power) offers a full range of high-performance, certified, and customizable power supply solutions, helping OEM clients meet their technical requirements and bring products to market with confidence.