1. Introduction

Selecting the right cable for a 12V DC power adapter is often overlooked, but it plays a critical role in ensuring stable output, long lifespan, and compliance with efficiency standards. The cable diameter affects voltage drop, heat generation, and whether the adapter can meet regulations such as DOE Level VI or EU EcoDesign.

2. Basics: Current, Voltage, and Cable Diameter

The resistance of a copper wire is determined by: R=ρ⋅LAR = \frac{\rho \cdot L}{A}R=Aρ⋅L

Where:

- RRR = resistance (Ω)

- ρ\rhoρ = resistivity of copper (~0.0172 Ω·mm²/m)

- LLL = length of the wire (m)

- AAA = cross-sectional area of the conductor (mm²)

Voltage drop along the wire can be calculated as: Vdrop=I⋅RroundtripV_{drop} = I \cdot R_{roundtrip}Vdrop=I⋅Rroundtrip

Where III is the current (A) and Rroundtrip=2RR_{roundtrip} = 2RRroundtrip=2R.

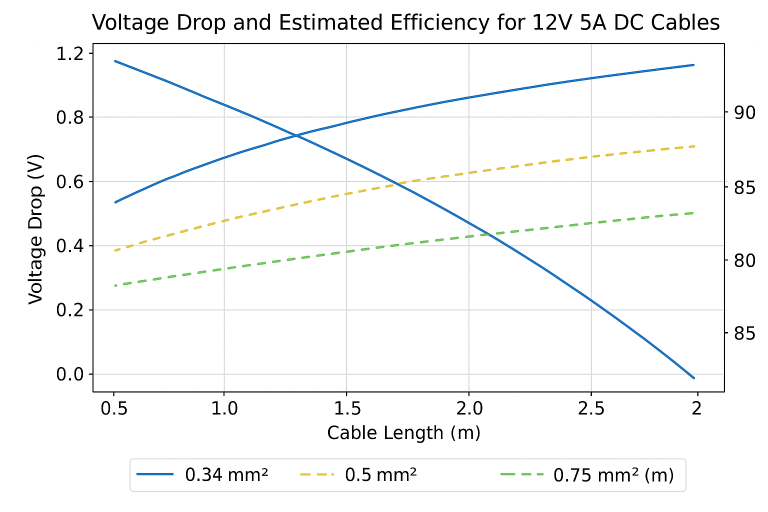

Example: 12V, 5A DC adapter

| Cable cross-section (mm²) | Cable length (m) | Round-trip resistance (Ω) | Voltage drop (V) | Voltage drop (%) |

|---|---|---|---|---|

| 0.34 (≈AWG22) | 1 | 0.101 | 0.505 | 4.2% |

| 0.5 (≈AWG20) | 1 | 0.0688 | 0.344 | 2.9% |

| 0.75 (≈AWG18) | 1 | 0.0458 | 0.229 | 1.9% |

Note: Voltage drop increases with cable length and decreases with larger conductor area.

3. Current Capacity and Heat

Continuous 5A load generates heat in the cable: Ploss=I2⋅RroundtripP_{loss} = I^2 \cdot R_{roundtrip}Ploss=I2⋅Rroundtrip

- Smaller cables heat up faster and may reduce lifespan.

- Multi-strand cables are more flexible and can carry slightly more current than solid wire of the same cross-section.

4. Efficiency Levels and Cable Diameter

Efficiency standards such as DOE Level VI (USA) and EU EcoDesign measure total system efficiency, including cable losses.

Example: 12V, 5A, 1.5m cable with 0.5 mm² conductor:

- Round-trip resistance ≈ 0.103 Ω

- Power loss Ploss=52×0.103≈2.58WP_{loss} = 5^2 × 0.103 ≈ 2.58 WPloss=52×0.103≈2.58W

- If adapter nominal output is 60W, efficiency drops from 90% to ~87.7% — potentially below required standard (88%).

Conclusion: Cable diameter directly affects whether the adapter can meet regulatory efficiency requirements.

5. Application-Specific Cable Selection

Different applications tolerate voltage drop differently:

| Application Type | Voltage Sensitivity | Recommended Minimum Cable |

|---|---|---|

| Precision electronics / medical | High | ≥0.75 mm² (5–6 mm OD) |

| LED lighting, motors | Medium | 0.5–0.75 mm² |

| Short cable, non-critical load | Low | 0.5 mm² (4 mm OD) |

- Longer cables require larger cross-section to maintain voltage.

- Short cables (<1 m) can use 0.5 mm², but voltage drop and heat should be considered.

6. Summary & Recommendations

- Confirm output current and cable length.

- Calculate minimum conductor size based on acceptable voltage drop and heat.

- For products sold in the EU or USA, prioritize compliance with DOE Level VI / EcoDesign.

- Use ≥0.75 mm² for 12V 5A adapters over 1.5 m for reliable performance and efficiency compliance.

- Provide clear tables or charts for customers to visualize voltage drop vs. cable diameter and length.

7. Practical Tip

- Example FAQ: “Can a 4 mm OD cable work for 12V 5A?” → Yes for short, non-critical applications, but may fail efficiency tests if Level VI/EcoDesign compliance is required.

- Always ask about the customer’s device/application to determine voltage sensitivity. You can check our 12V Power Adapters for models optimized for stable voltage and high efficiency.

This article helps customers understand why cable selection matters for performance, safety, and efficiency compliance, while demonstrating your expertise in DC power solutions.

12V 5A DC Cable Voltage Drop and Efficiency

| Cable Diameter (mm²) | Cable Length (m) | Round-Trip Resistance (Ω) | Voltage Drop (V) | Voltage Drop (%) | Line Loss (W) | Estimated Efficiency* (%) |

|---|---|---|---|---|---|---|

| 0.34 | 1 | 0.101 | 0.505 | 4.2% | 2.53 | 87.7 |

| 0.34 | 1.5 | 0.152 | 0.758 | 6.3% | 3.79 | 86.5 |

| 0.5 | 1 | 0.0688 | 0.344 | 2.9% | 1.72 | 88.9 |

| 0.5 | 1.5 | 0.1032 | 0.516 | 4.3% | 2.58 | 87.7 |

| 0.75 | 1 | 0.0458 | 0.229 | 1.9% | 1.14 | 89.6 |

| 0.75 | 1.5 | 0.0687 | 0.344 | 2.9% | 1.72 | 88.9 |

*Assuming adapter internal efficiency = 90% at full load without cable losses.

More Guides for choosing the right Power adapter:

How to match voltage, current and connector type.