1. The Real Question Engineers Should Ask

When designing a power system for embedded or industrial equipment, the question is rarely “Which power supply is more efficient?”

The real question is:

Where should power conversion happen within the system architecture?

Choosing between AC-DC and DC-DC power supplies is not a component-level decision—it defines safety boundaries, thermal behavior, EMC performance, scalability, and long-term reliability of the entire system.

2. What AC-DC and DC-DC Power Supplies Actually Do

At a functional level:

- AC-DC power supplies convert mains voltage (e.g., 100–240VAC) into a low-voltage DC rail.

- DC-DC converters convert one DC voltage level to another, often closer to the load.

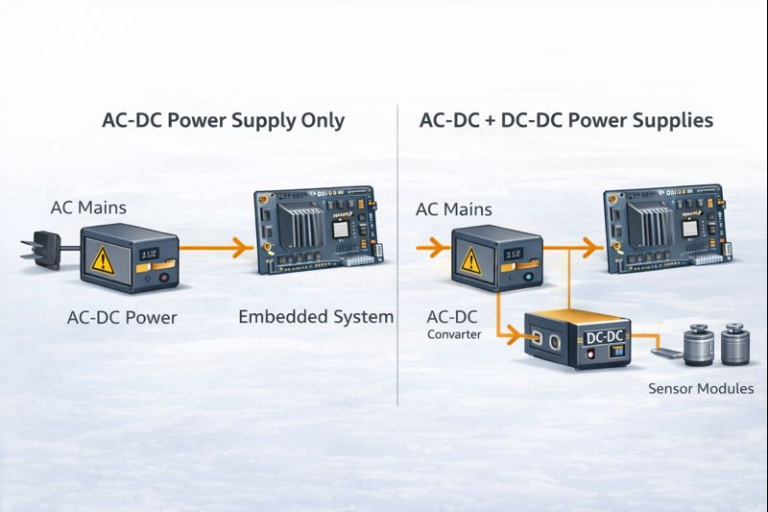

However, in real-world systems, these two are not alternatives.

They are typically used together, at different layers of the power architecture.

A common misconception among less-experienced designers is treating AC-DC and DC-DC as interchangeable options. In practice, they serve fundamentally different roles.

3. Typical Power Architectures in Embedded and Industrial Systems

Most reliable systems follow one of these architectures:

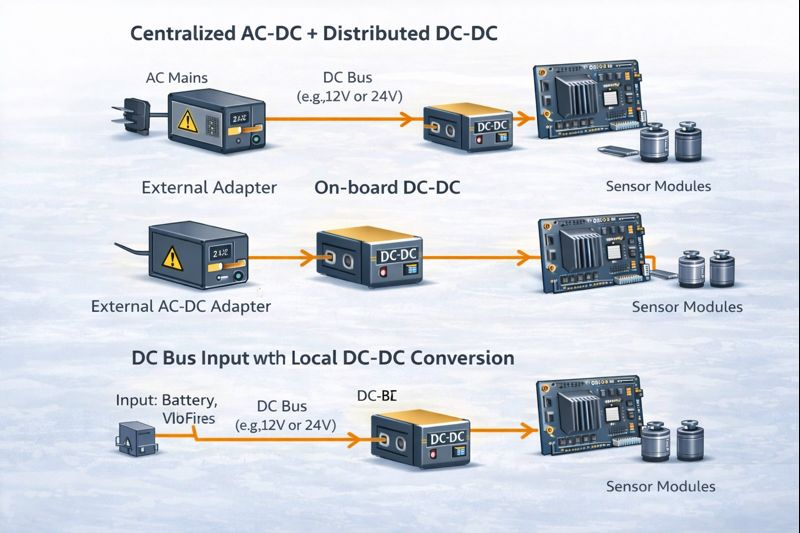

Centralized AC-DC + Distributed DC-DC

- One AC-DC power supply generates a main DC bus (e.g., 24V or 12V)

- Multiple DC-DC converters regulate voltage locally for processors, sensors, and interfaces

This approach is common in:

- Industrial controllers

- Automation panels

- Communication equipment

External AC-DC Adapter + On-board DC-DC

- An external adapter handles mains isolation and safety

- DC-DC converters on the PCB generate required rails

Typical for:

- Embedded devices

- Medical and test equipment

- Compact systems with limited internal space

DC Bus Input + Local DC-DC Conversion

- System is powered by an existing DC source (battery, vehicle bus, or centralized supply)

- Only DC-DC converters are required internally

Used in:

- Battery-powered systems

- Telecom and transportation equipment

Understanding which architecture applies to your system is the foundation of a correct AC-DC vs DC-DC decision.

4. Key Factors When Choosing Between AC-DC and DC-DC

4.1 Input Power Source

If your system connects directly to mains power, AC-DC conversion is mandatory.

DC-DC converters alone cannot provide isolation or meet safety requirements for mains-connected equipment.

If the input is already DC, then DC-DC becomes the primary choice.

4.2 Safety and Isolation Requirements

AC-DC power supplies provide reinforced or basic isolation between mains and low-voltage circuits.

This is critical for:

- Industrial safety compliance

- Medical and laboratory equipment

- User-accessible electronics

Using a DC-DC converter where isolation is required is one of the most common—and dangerous—design mistakes.

4.3 Power Level and Load Distribution

AC-DC power supplies are typically used for:

- Tens to hundreds of watts

- Supplying a shared DC rail

DC-DC converters excel at:

- Point-of-load regulation

- Handling fast transient loads

- Improving local voltage stability

High-performance systems often rely on DC-DC converters even when a capable AC-DC supply is already present.

4.4 Thermal and Mechanical Constraints

AC-DC power supplies tend to:

- Generate more heat

- Require airflow or heat sinking

- Occupy more volume

DC-DC converters:

- Can be placed near loads

- Reduce copper losses on the PCB

- Improve thermal distribution across the system

Enclosed industrial systems often depend on DC-DC conversion to avoid localized hot spots.

4.5 EMC and Noise Considerations

AC-DC supplies deal with:

- Conducted emissions on the mains

- High-energy switching noise

DC-DC converters introduce:

- High-frequency noise close to sensitive circuits

The correct choice—and placement—of each stage has a direct impact on EMC compliance and signal integrity.

5. Common Design Mistakes

Engineers frequently encounter issues due to early architectural decisions:

- Using DC-DC converters without proper isolation in mains-powered systems

- Oversizing AC-DC supplies while ignoring point-of-load regulation

- Assuming efficiency alone determines system reliability

- Underestimating startup current and transient load behavior

Most of these issues originate from treating AC-DC vs DC-DC as a component choice instead of a system-level decision.

6. How This Decision Affects the Rest of the Power Design

The AC-DC vs DC-DC choice directly influences:

- Power margin calculations

- Thermal management strategies

- EMC filtering and grounding

- Redundant and backup power architectures

In fact, nearly every downstream power design decision depends on this initial architectural choice.

This is why experienced designers address AC-DC vs DC-DC before selecting specific models or ratings.

7. Practical Recommendations

There is no universal “correct” choice between AC-DC and DC-DC power supplies.

Instead:

- Use AC-DC to handle mains input, safety isolation, and bulk power conversion.

- Use DC-DC for voltage regulation close to the load, thermal optimization, and performance stability.

- Treat power design as a layered architecture, not a single component decision.

A reliable embedded or industrial power system is built by combining both appropriately—not by choosing one over the other.